不(bu)銹鋼閘閥(fa)

銹鋼美(mei)標(biao)閘閥(fa).jpg)

不(bu)銹鋼美(mei)標(biao)閘閥(fa)

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)適(shi)用(yong)於(yu)ANSI Class150~2500LB,工(gong)作溫(wen)度(du)-40~500℃的(de)各(ge)種(zhong)管路上,用(yong)於(yu)截(jie)斷或(huo)接(jie)通(tong)管路中的介質(zhi)。通過選(xuan)用(yong)不(bu)同的材(cai)質(zhi),可適用(yong)於(yu)水(shui)、蒸汽、油(you)品、強(qiang)氧化(hua)性介質(zhi)及尿(niao)素等多種(zhong)介質(zhi)。

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)產品概(gai)述:

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)適(shi)用(yong)於(yu)ANSI Class150~2500LB,工(gong)作溫(wen)度(du)-40~500℃的(de)各(ge)種(zhong)管路上,用(yong)於(yu)截(jie)斷或(huo)接(jie)通(tong)管路中的介質(zhi)。通過選(xuan)用(yong)不(bu)同的材(cai)質(zhi),可適用(yong)於(yu)水(shui)、蒸汽、油(you)品、強(qiang)氧化(hua)性介質(zhi)及尿(niao)素等多種(zhong)介質(zhi)。有(you)手(shou)動、傘齒(chi)輪傳(chuan)動及電(dian)動等。楔式(shi)閘閥(fa)的(de)閘板(ban)可以做(zuo)成壹(yi)個(ge)整(zheng)體(ti),叫(jiao)做剛(gang)性閘板(ban);也可(ke)以做(zuo)成能(neng)產生(sheng)微量變形(xing)的閘板(ban),以改善其工藝(yi)性(xing),彌(mi)補密(mi)封(feng)面角度(du)在(zai)加工過(guo)程(cheng)中產生(sheng)的(de)偏(pian)差,這(zhe)種(zhong)閘板(ban)叫(jiao)做彈(dan)性閘板(ban)。

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)產品特(te)點(dian):

1、國內外(wai)先進標(biao)準(zhun)的要(yao)求(qiu),密封(feng)可(ke)靠,性能(neng)優良(liang),造型美(mei)觀(guan)。

3、采用(yong)楔(xie)式(shi)彈性(xing)閘板(ban)結構,中大口(kou)徑(jing)設置(zhi)滾動軸承(cheng),啟(qi)閉輕(qing)松(song)。

4、閥(fa)桿(gan)經(jing)調質和表(biao)面氮(dan)化(hua)處理(li),有(you)良(liang)好的搞(gao)腐(fu)蝕(shi)性(xing)和抗(kang)擦(ca)傷(shang)性(xing)。

2、閘板(ban)、閥座(zuo)耐(nai)磨(mo)、耐高(gao)溫(wen),耐(nai)腐蝕(shi),抗(kang)擦(ca)傷(shang)性(xing)能(neng)好、使用(yong)壽命(ming)長。

5、可采用(yong)各(ge)種(zhong)配管法蘭標(biao)準(zhun)及法(fa)蘭密封(feng)面型式(shi),滿足(zu)各(ge)種(zhong)工程(cheng)需要及用(yong)戶(hu)要(yao)求(qiu)。

6、閥體(ti)材(cai)料品種(zhong)齊(qi)全(quan),填料、墊片根據(ju)實(shi)際(ji)工(gong)況或(huo)用(yong)戶(hu)要(yao)求(qiu)合(he)理(li)選(xuan)配,能(neng)適用(yong)於(yu)各(ge)種(zhong)壓力(li)、溫度(du)及介質(zhi)工況。

Z41H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)產品作用(yong):

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)是作為(wei)截(jie)止介質(zhi)使用(yong),在(zai)全(quan)開時(shi)整(zheng)個(ge)流通直(zhi)通,此(ci)時(shi)介質(zhi)運行(xing)的壓(ya)力(li)損失(shi)很小(xiao)。API gate valve 鋼制法蘭閘閥(fa)通(tong)常適用(yong)於(yu)不(bu)需要經(jing)常啟閉(bi),而且(qie)保(bao)持閘板(ban)全開或(huo)全(quan)閉(bi)的(de)工(gong)況,不(bu)適用(yong)於(yu)作為(wei)調(tiao)節或(huo)節流(liu)使用(yong)。對於(yu)高(gao)速(su)流(liu)動的介質(zhi),美(mei)標(biao)閘閥(fa)的(de)閘板(ban)在局部開啟(qi)狀(zhuang)況下可(ke)以引起閘門(men)的振動,而振動又可(ke)能(neng)損傷(shang)閘板(ban)和閥(fa)座(zuo)的(de)密(mi)封(feng)面,而節流(liu)會使閘板(ban)遭(zao)受介質(zhi)的沖蝕(shi)。從結構形式(shi)上,主要的(de)區別是所采用(yong)的(de)密(mi)封(feng)元(yuan)件的形(xing)式(shi)。

Z41H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)制造標(biao)準(zhun):

| 設計(ji)與(yu)制造 Design and Manufacture | 結構長度(du) Face to face/ End to end | 法(fa)蘭尺寸 FlangeDimension | 對焊(han)連接尺寸 Butt welding dimension | 壓(ya)力(li)-溫度(du)Pressure Temperature Lating | 試(shi)驗(yan)-檢驗(yan)Inspection and Test |

| API 600 | ANSI B16.10 | ANSI B16.5 | ANSI B16.25 | ANSI B16.34 | API 598 |

| API 6D | API 6D | ANSI B16.5 | ANSI B16.25 | ANSI B16.34 | API 6D |

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)壓(ya)力(li)試驗(yan):

| 公(gong)稱(cheng)壓力(li)PN(Lb) NominalPressure | 強度(du)試(shi)驗(yan) Shell Test | 水(shui)密封(feng)試(shi)驗(yan) WaterSeal Test | 氣(qi)密封(feng)試(shi)驗(yan) Air SealTest | |||

| MPa | Lbf/in2 | MPa | Lbf/in2 | MPa | Lbf/in2 | |

| 150 | 3.0 | 430 | 2.2 | 315 | 0.4-0.7 | 60-100 |

| 300 | 7.7 | 1110 | 5.7 | 815 | ||

| 600 | 15.3 | 2220 | 11.3 | 630 | ||

| 900 | 23.0 | 3330 | 17 | 2445 | ||

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)主要零(ling)件材(cai)料及性(xing)能(neng):

| 殼(ke)體 | ASTM A216WCB | ASTMA351 CF8 | |||||||||

| 閘板(ban) | WCB | CF8 | CF8M | Monel | |||||||

| 閥桿(gan) | F6a | F304 | F316 | Monel | F304 | ||||||

| 閘板(ban)密封(feng)面 | 13Cr | 13Cr | STL | 304 | STL | 316 | STL | Monel | 304 | 304 | STL |

| 閥座(zuo)密(mi)封(feng)面 | 13Cr | STL | STL | 304 | STL | 316 | STL | Monel | 304 | STL | STL |

| 殼(ke)體 | ASTM A351 CF3 | ADTM A351 CF8M | ASTM A351 CF8 | ||||||||

| 閘板(ban) | |||||||||||

| 閥桿(gan) | F304L | F316 | F316L | ||||||||

| 閘板(ban)密封(feng)面 | 304L | 304L | STL | 316 | 316 | STL | 316L | 316L | STL | ||

| 閥座(zuo)密(mi)封(feng)面 | 304L | STL | STL | 316 | STL | STL | 316L | STL | STL | ||

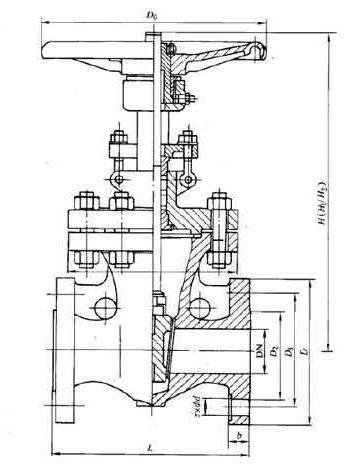

Z40H 不(bu)銹鋼美(mei)標(biao)閘閥(fa)主要尺寸:

| ANS1 Class150 | |||||||||||||||||||||

| NPS | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 | 40 | 42 | |

| L | RF | 178 | 191 | 203 | 29 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | 559 | 610 | 610 | 660 | 711 | 762 | 787 |

| BW | 216 | 241 | 283 | 305 | 403 | 419 | 457 | 502 | 572 | 610 | 660 | 711 | 813 | 864 | 914 | 914 | 965 | 1016 | 1067 | 1118 | |

| 手(shou)動 | H1 | 400 | 490 | 510 | 585 | 775 | 955 | 1160 | 1375 | 1570 | 1765 | 1980 | - | - | - | - | - | - | - | - | - |

| Do | 200 | 200 | 250 | 300 | 350 | 350 | 400 | 450 | 500 | 600 | 700 | - | - | - | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | - | - | - | - | - | 1668 | 1920 | 2115 | 2215 | 2600 | 2908 | 3046 | 3136 | 3293 | 3726 | 4060 | 4229 |

| 電(dian)動 | H3 | - | - | - | - | - | - | - | - | 1668 | 1920 | 2115 | 2215 | 2600 | 2908 | 3046 | 3136 | 3293 | 3726 | 4060 | 4229 |

| ANS1 Class300 | |||||||||||||||||||||

| NPS | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 | 40 | 42 | |

| L | RF | 216 | 241 | 283 | 305 | 406 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 | 1245 | 1346 | 1697 | 1524 | 1727 | - | - |

| BW | 216 | 241 | 283 | 305 | 406 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 | 1245 | 1346 | 1697 | 1524 | 1727 | - | - | |

| 手(shou)動 | H1 | 470 | 525 | 535 | 635 | 805 | 1025 | 1230 | 1460 | 1645 | - | 1840 | - | - | - | - | - | - | - | - | - |

| Do | 200 | 200 | 300 | 300 | 350 | 400 | 450 | 500 | 600 | - | 600 | - | - | - | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | - | - | - | - | - | - | - | 1935 | 2155 | 2572 | 2908 | 3100 | 3135 | 3293 | - | - | - |

| 電(dian)動 | H3 | - | - | - | - | - | - | - | - | - | - | 1935 | 2155 | 2572 | 2908 | 3100 | 3135 | 3293 | 3754 | 4120 | 4530 |

| ANS1 Class600 | |||||||||||||||||

| NPS | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | |

| L | RF | 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 990 | 1092 | 1194 | 1397 | 1448 | 1549 | 1651 |

| BW | 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 990 | 1092 | 1194 | 1397 | 1448 | 1549 | 1651 | |

| 手(shou)動 | H1 | 474 | 530 | 547 | 703 | 913 | 1077 | 1276 | 1499 | - | - | - | - | - | - | - | - |

| Do | 250 | 250 | 300 | 350 | 450 | 500 | 600 | 680 | - | - | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | - | - | - | - | 1470 | 16250 | 2089 | 2211 | 2616 | 2921 | 2960 | 3050 | 3112 |

| 電(dian)動 | H3 | - | - | - | - | - | - | - | 1470 | 16250 | 2089 | 2211 | 2616 | 2921 | 2960 | 3050 | 3112 |

| ANS1 Class900 | |||||||||||||

| NPS | 2 | 21/2 | 3 | 4 | 6 | 8 | 12 | 14 | 16 | 18 | 20 | 24 | |

| L | RF | 368 | 419 | 381 | 457 | 610 | 737 | 965 | 1029 | 1130 | 1217 | 1321 | 1549 |

| BW | 368 | 419 | 381 | 457 | 610 | 737 | - | - | - | - | - | - | |

| 手(shou)動 | H1 | 620 | 705 | 695 | 825 | 1065 | 1318 | - | - | - | - | - | - |

| Do | 300 | 350 | 350 | 400 | 500 | 600 | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | - | 800 | 940 | 1691 | 1877 | 2143 | 2310 | 2750 | 3150 |

| 電(dian)動 | H3 | - | - | - | - | 800 | 940 | 1691 | 1877 | 2143 | 2310 | 2750 | 3150 |

| ANS1 Class1500 | |||||||||||||

| NPS | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| L | RF | 371 | 473 | 549 | - | - | - | - | - | - | - | - | - |

| BW | - | - | - | - | - | - | - | - | - | - | - | - | |

| 手(shou)動 | H1 | 614 | 705 | 927 | 1191 | 1524 | 1854 | 2184 | 2216 | - | - | - | - |

| Do | - | - | - | - | - | - | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | 1191 | 1524 | 1854 | 2184 | - | - | - | - | - |

| 電(dian)動 | H3 | - | - | - | 1191 | 1524 | 1854 | 2184 | 2216 | 2316 | 2620 | 2840 | 3310 |

| ANS1 Class2500 | ||||||||

| NPS | 2 | 3 | 4 | 6 | 8 | 10 | 12 | |

| L | RF | 451 | 578 | 673 | 914 | 1022 | 1270 | 1422 |

| BW | 451 | 578 | 673 | 914 | 1022 | 1270 | 1422 | |

| 手(shou)動 | H1 | 630 | 890 | - | - | - | - | - |

| Do | - | - | - | - | - | - | - | |

| 傘齒(chi)輪 | H2 | - | - | - | - | - | - | - |

| 電(dian)動 | H3 | - | - | 191 | 1347 | 1445 | 1692 | 1914 |

相關(guan)產品

銹鋼全(quan)封(feng)閉(bi)式(shi)刀閘閥(fa).jpg)

銹鋼保(bao)溫閘閥(fa).jpg)

銹鋼刀型閘閥(fa).jpg)